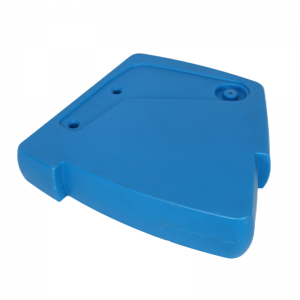

Customized Seat Parts: Unleashing Possibilities through Blow Molding

As a dedicated blow molding factory, we take pride in offering a wide range of customized seat parts to meet the unique requirements of our clients. From blow molding plastic armrests to providing comprehensive services including mold production, samples, production, and packaging, we are committed to delivering exceptional quality and tailored solutions. In this article, we will showcase our expertise in providing customized seat parts services, highlighting each step of the process, from design to shipping.

At our blow molding factory, we understand the importance of customization in seat parts. We work closely with our clients to conceptualize and design plastic armrests that align with their specific needs. Our team of skilled designers and engineers combines creativity with technical expertise to transform ideas into functional and visually appealing seat parts.

Once the design is finalized, we initiate the mold production process. Our experienced mold production team utilizes advanced technology and state-of-the-art equipment to manufacture high-quality molds. With precision engineering and attention to detail, we ensure that the molds meet your exact specifications, guaranteeing consistent and accurate production of plastic armrests.

Upon the completion of mold production, we provide samples of the blow molded plastic armrests for your evaluation. We understand the significance of assessing the functionality, fit, and finish of the parts. These samples allow you to verify the design, make any necessary adjustments, and ensure that the final product meets your expectations.

Once you have approved the samples, we proceed with mass production. Our modern blow molding machines, operated by skilled technicians, enable efficient and high-volume production of plastic armrests. We maintain stringent quality control measures throughout the manufacturing process to ensure consistent quality and adherence to your specifications.

We recognize the importance of packaging in protecting seat parts during transportation and enhancing their presentation. Our packaging experts collaborate closely with you to create customized packaging solutions. We use suitable materials, such as protective wraps, containers, or boxes, to ensure that your plastic armrests reach their destination in optimal condition. Additionally, we can incorporate your branding elements to enhance the visual appeal of the packaging.

Timely delivery is a top priority for us. Our logistics team works in collaboration with reliable shipping partners to ensure that your seat parts are shipped efficiently and reach you on time. We offer flexible shipping options, including domestic and international shipping, to accommodate your specific requirements. Our goal is to provide a seamless experience from production to delivery, ensuring your complete satisfaction.

As a leading blow molding factory, we specialize in providing customized seat parts services, including blow molding plastic armrests, mold production, samples, production, and packaging. With a focus on design, precision mold production, efficient production processes, and reliable shipping, we aim to deliver seat parts that exceed your expectations. Partner with us to unleash the possibilities of customized seat parts and experience outstanding quality and service