-

Key points of mold and accessory design

The mold usually has only the cavity part and no punch. The mold surface generally does not need to be hardened. The blow pressure borne by the cavity is much smaller than that of injection molding, generally 0.2~1.0MPG, and the cost is low. ...Read more -

Mastering Blow Molded Product Design: From R Transitions to Material Selection

Introduction to Design Blow-molded products are widely used in various industries, especially in the beverage and drug packaging industry, and also in the toy industry. Make R transition at edges and corners Generally, the cor...Read more -

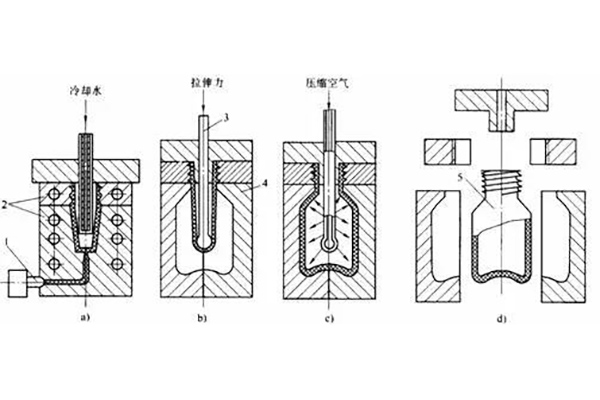

Introduction to Blow Molding Technology

Blow molding, also known as hollow blow molding, is a rapidly developing plastic processing method. During the Second World War, the blow molding process began to be used to produce low density polyethylene vials. In the late 1950s, with the birth of high-density polyeth...Read more -

Defects and elimination of various blow molding processes

The longitudinal wall thickness of blow molded products is uneven Cause: 1. The self-weight sag of the parison is serious 2. The diameter difference between the two longitudinal cross sections of blow-molded products is too large Solution: 1. Reduce the melt temperature ...Read more -

An In-Depth Look at Extrusion Blow Molding (EBM)

Blow molding mainly includes extrusion blow molding (EBM), injection stretch blow molding (ISBM) and injection blow molding (IBM). It is a molding process specially used for mass production of hollow plastic containers. This issue introduces three types of blow molding p...Read more

Hello, come to consult our products !